Quartz heating is a term that often crops up when people talk about types of heating. It's a phrase that we here at Tansun coined many years ago but which has now become synonymous with infrared heating. However, not everyone is clear exactly what it means. In this article we answer some of the most commonly-asked questions about this form of heating.

What Is Quartz Heating?

Quartz heating is a type of radiant heating, commonly referred to as short-wave infrared heating.

Radiant heating uses infrared waves to directly heat the surfaces of objects. All objects emit and absorb infrared heat, which is part of the electromagnetic spectrum with a frequency below visible light. Hotter objects will radiate more of this heat. This is the basis of the technology for most quartz heaters.

How was it discovered?

Infrared heat was discovered in the early 19th century by William Herschel, who named the invisible light as ‘infrared’ because he believed it was ‘below the red light,’ as ‘infra’ in Latin translates to ‘below.’ This meant that Herschel discovered a form of light beyond red light in the electromagnetic spectrum and it marked the first time in history that someone showed there were types of light that cannot be seen by the naked eye. The very first quartz heaters used what is known as ‘near infrared’ or ‘short wave infrared,’ which is closest to red in the light spectrum and able to contain large amounts of heat.

How Does It Work?

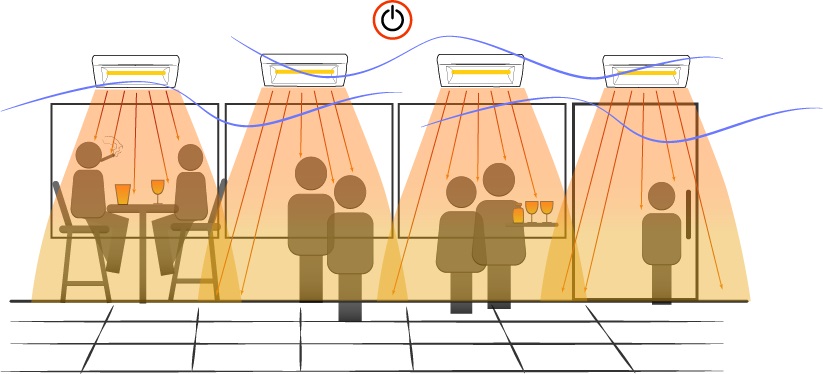

The principle is well-known and has been in use for many years. Electric infrared energy travels in straight lines from the heat source. This energy is directed into specific patterns by optically designed reflectors. Infrared, like light, travels outward from the heat source and diffuses over a distance.

This form of heating works similar to the sun, travelling in parallel lines, even able to pass through the vacuum of space. This is why quartz heating is not affected by wind and able to directly heat people and objects. These heaters are suitable for outdoor heating as well as indoor heating and due to their heat intensity, are also highly effective for space heating.

How do Quartz Heaters Work?

A quartz heater is a common type of infrared heater and the creation and subsequent release of heat from the heater is made by the heating element, enclosed in a quartz tube. The heating element produces heat at the necessary wavelength to create the appropriate level of intensity to heat the specific material required. The purpose of the tube is to protect the heating element and also to stop the escape of convection heat.

The principle of quartz heating works with the heating element becoming very hot and the quartz tube experiencing a sudden build up of heat. When the tube reaches the appropriate temperature, the heat is emitted out of the tube. The wavelength of heat produced from this process has been acknowledged as ideal for the human body. The infrared heat is directly absorbed by the people and objects near the heater and very little heat is absorbed by the air, due to the infrared spectrum being almost completely outside the absorption spectrum of air.

If you'd like to learn more about short, medium and long wave quartz heating, please visit our info page on

Types of Heating.

What is a Short Wave Lamp?

Short wave halogen heat lamps consist of a tungsten filament heated by the passage of an electric current to a temperature of about 2200º Celsius. At this temperature most of the emission is in the short wave infrared band (1.2 microns). However, as with all tungsten filament lamps, the tungsten will evaporate in time and deposit itself on the wall of the lamp.

To prevent this undesirable effect, a small amount of halogen gas is added to the envelope of the lamp and hence a process of re-composition takes place. As the tungsten evaporates it will combine with the halogen gas to form a tungsten halide and so prevent the tungsten being deposited in the wall of the lamp. The tungsten halide will re-combine with the filament, releasing the halogen and re-depositing the tungsten on the filament. This process is a continuous one and is known as the halogen cycle.

For heating applications, a ruby sleeve or gold dichroic coating encloses the halogen heat lamp to filter out the intense white light and provide a pleasant warm glow.

There are important differences between long wave emitters such as the metal sheath and medium or short wave emitter quartz lamps. For example, the radiant efficiency of a short wave quartz heater is up to 96% and that of a medium wave heater is around 60%.

How Do I Work Out How Many Heaters I Need?

For successful comfort heating, there must be reasonably even levels of heat throughout the area to be heated. Proper mounting heights of the individual quartz heaters, accurate heater spacing, reflector beam patterns, and heat wattage must all be specified to generate the proper heating levels at the task area.

The amount of heat delivered can also be adjusted by heater controllers which can provide on-off or variable outputs. Quartz heaters are perfect for a wide range of heating applications and heating sectors. Take a look at some of our ranges which are featured below. Also, visit our

Guide To Buying Quartz Heaters for more information.

Tansun provides a free heating design service upon request where we can use more than 35 years of experience in the heating industry to provide you with innovative quartz heaters for any scheme you require. Please call us at 0121 580 6200 or email our dedicated sales team at sales@tansun.com to help provide you with the correct quartz heaters for your scheme.